Residual Biomass Based Wood Pellets

Utilizing Pacific North West’s (PNW) residual biomass for export-oriented wood pellet production

Forests of PNW

The Pacific Northwest (PNW), especially Washington and Oregon, is known for its thriving and sustainable forestry industry. Over 91.3% of Washington’s and 53.4% of Oregon’s working forests, (i.e., forests that are managed for timber) are third-party certified, either by the Sustainable Forestry Initiative (SFI), the Forest Stewardship Council (FSC), or the American Tree Farm System (ATFS).

What is Residual Biomass?

Residual biomass can primarily be of two forms, Harvest Residue and Mill Residue. Harvest residue comprises of treetops and branches left on the forest floor following harvest operations. This unused biomass is commonly termed ‘harvest slash’ and is either piled and burned to prevent forest fires or left on the forest floor to decay. Mill residues constitute bark, wood chips, sawdust, and shavings produced in sawn lumber or other wood products manufacturing. This residual biomass is either burnt in hog fuel boilers to dry wood or sold in the market for pulping or other uses. Given the steady decline in demand from the pulping sec-tor, the wood products manufacturers need alternate markets for this residual biomass.

Environmental and economic costs of residual biomass

If left on the forest floor, the accumulated harvest slash can fuel forest fires resulting in uncontrollable wildfires. Thereby, it’s critical to reduce the residue buildup on the forest floor by using controlled prescribed open burns. However, prescribed burning also comes with environmental problems, as it emits dangerous levels of particulate matter and other chemicals, impacting the local air quality. The budget for controlling wildfires in the PNW ballooned over the past decade, ranging between $200 million to $400 million per annum. The cost of prescribed burns also runs in tens of millions of dollars. None of these costs account for the loss of hundreds of millions of dollars worth of forest resources and their impact on climate change.

Residual biomass-based wood pellets industry in the Pacific Northwest

Wood pellets are biofuels made from compacted biomass. Any low-quality bio-mass such as forest residues or hog fuel can be used to produce wood pellets. Utilizing this residual biomass to manufacture wood pellets will solve the regional environmental and economic problems associated with biomass disposal and create local jobs. Such an industry will also provide a market for this residual biomass, offer a financial incentive for forest health management, and mitigate catastrophic forest fire risks. The wood pellets produced with this waste biomass can help displace harmful fossil fuels like coal and natural gas.

Further value addition of these wood pellets is possible, enhancing the properties of pellets as a viable bioenergy alternative. For example, roasting the wood pellets in an anaerobic condition (i.e., pyrolysis) will add value to the wood pellets by increasing the heat content and physical properties. This process is known as torrefaction, and the torrefied pellets are also known as black pellets.

Why export-oriented industry?

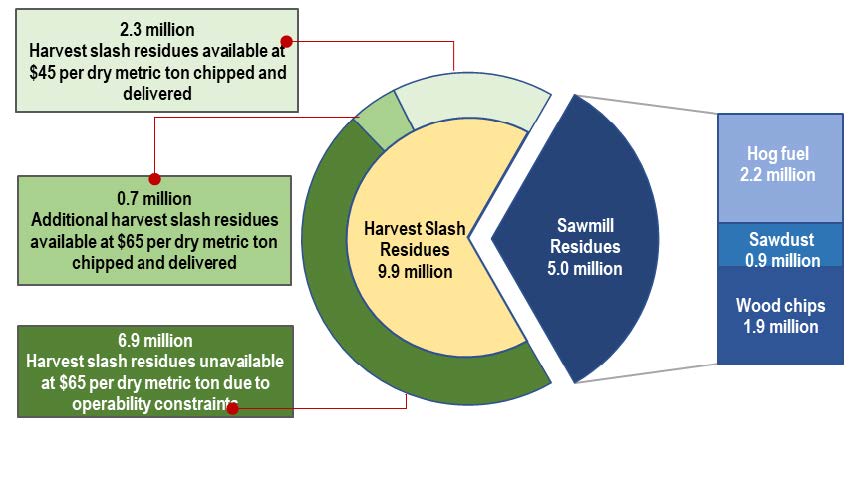

As seen in Figure 1, PNW generates around 9.9 million dry metric tons of harvest residues and 5 million dry tons of mill residues every year. Between 2 to 4 million dry metric tons of this residual biomass could be made available for an economically viable pellet production industry in the State.

To consume such large volumes of woody biomass-based biofuel, we need to have the necessary amount of dedicated biomass boilers or co-firing facilities. Moreover, the need for biomass-based energy in the PNW is limited, given that a large proportion of our energy grid constitutes non-fossil-based energy, including hydro, solar, and nuclear. However, in Asia, especially in Japan and S. Korea, there is a massive and growing demand for sustainable woody biomass for displacing fossil-based energy. Hence, the surplus unutilized sustainable biomass in Washington State can meet the biomass-based energy demand in East Asian countries. Thus, Washington’s export-oriented wood pellet industry presents one of the rare environmental and economic win-win scenarios at local and global levels.

The environmental benefits of wood pellets as a fossil fuel substitute

To understand the environmental benefits of wood pellets as a biofuel alternative, we conducted a detailed cradle-to-grave Life cycle assessment (LCA). In this analysis, we assessed environmental impacts associated with all the stages of the product life-cycle, including:

- feedstock extraction and transportation to the manufacturing facility

- feedstock processing and pellet manufacturing

- local truck transportation to shipping port

- ocean transportation to a port in Japan, and

- electricity generation at a bioenergy plan in Japan.

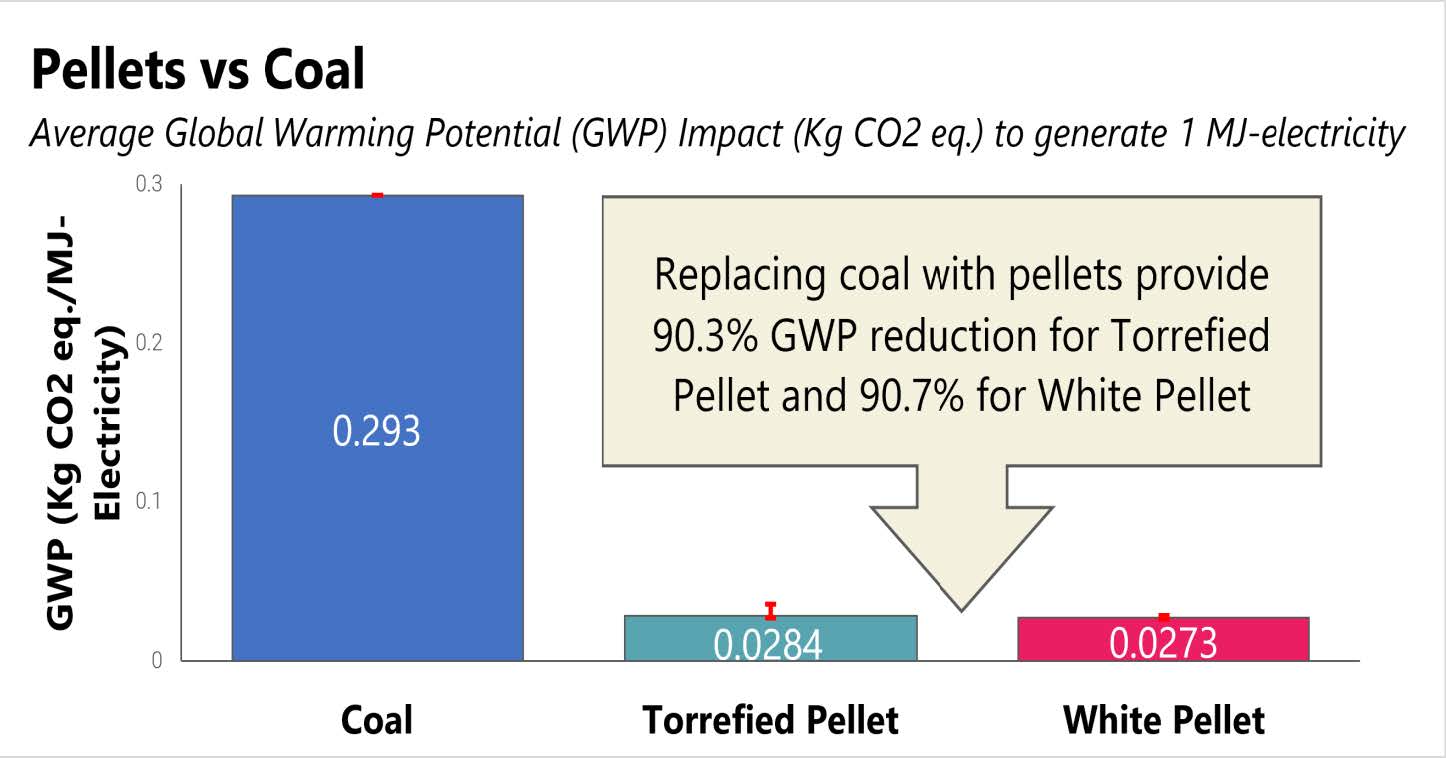

We developed a parallel cradle-to-grave LCA for coal with comparable and relevant parameters to conduct a comparative assess-ment. The results show that pellets produced from residues in Washington State and used for electricity general at a bioenergy facil-ity in Japan would reduce net greenhouse gas emissions (GHG) by over 90%, compared to existing cradle-to-grave coal-based energy. This emission reduction results in an equivalent reduction in the Global Warming Potential of the corresponding energy produced. It is important to note that biomass burned in a controlled environment, like a bioenergy facility, emits 95% less pollutants to the atmosphere as compared to open biomass burns (i.e., prescribed burns or wildfires). After factoring in all the particulate matter emissions of harvesting, processing, local and international transportation, harvest-slash-based pellets reduce help reduce PM2.5 pollution by 88%, with most of this clean air benefit going to communities in Washington State.

Takeaways

- The Pacific Northwest produces large amounts of residual biomass, a significant proportion of which is treated as waste and disposed of through open prescribed burns.

- This ‘waste’ biomass can be converted to wood pellet and used as a bioenergy alternative.

- Pellets produced from residues on average produce 90% less greenhouse gas emissions (GHG) compared to coal.

- Utilizing harvest slash residues for pellet production instead of burning reduce the local PM2.5 pollution by 88%.

- An export oriented pellet industry in the PNW is a win-win solution for the global environment and the local economy.